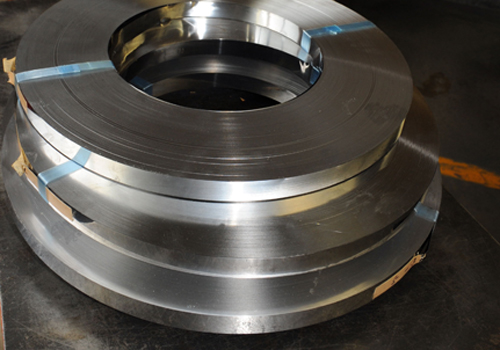

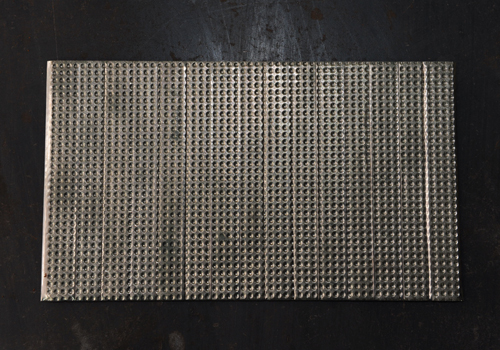

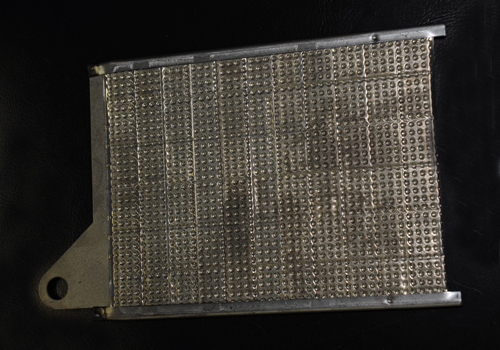

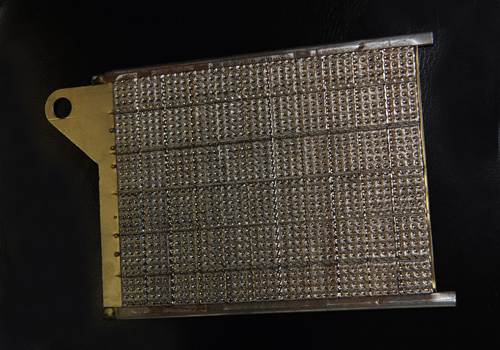

Steel thin tape is perforated by needles. The active material is enclosed in the so-called pockets out of the perforated tape. The individual pockets are mechanically interconnected with one another, so this interconnected pocket is in the form of one plate. Plate tab and plate frame are fixed to this plate by mechanical press, so electrode plate is completed.

Active material

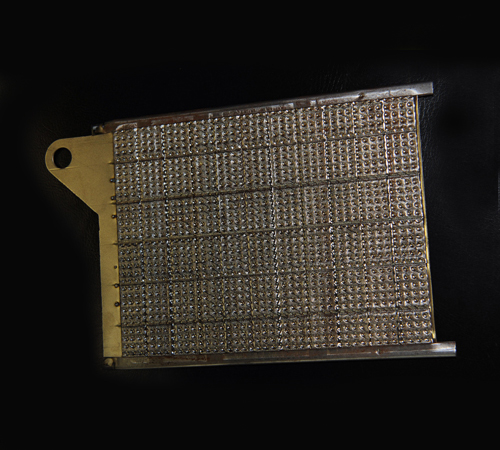

tape

(before perforation)

tape(after perforation)

tube

mat (electrode)

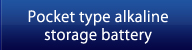

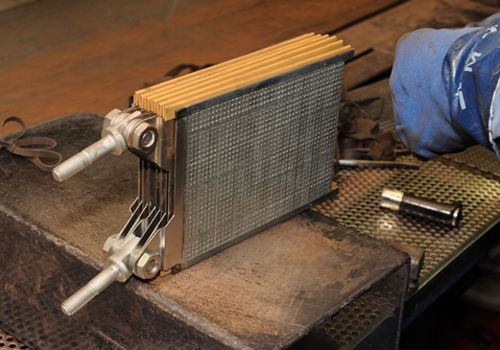

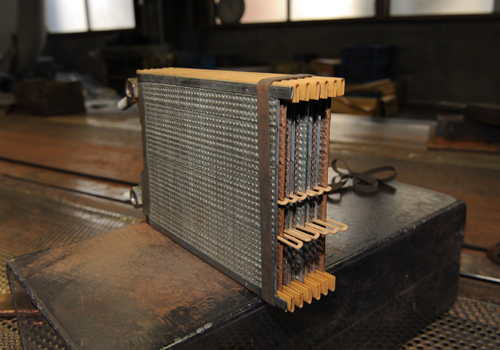

Electrode plates are stacked. Post of a battery and related parts are also attached. And separators are inserted into assembled electrode plate group and separator edges are put in order by machine. Electrode plate group is tightened by resin band using binding machine. So electrode plate group is completed.

Plate group(Positive)

Plate group(Negative)

The combination of

positive and negative

plate group,

put on the side

insulation separator

Insert pin-shaped

separator between

plates

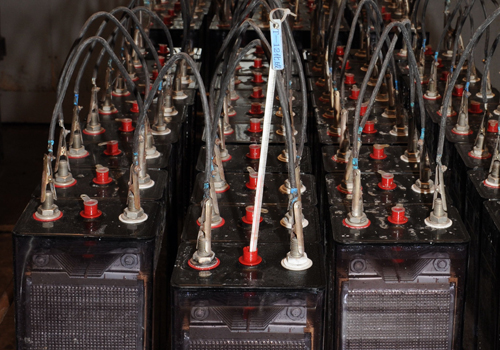

Plates group is activated by repeat of charging and discharging so as to have rated capacity. Next, the electrode plate group is installed in a container and lid is attached to it. The cell is filled with electrolyte and charged to the rated capacity. So, cell assembled cell group and relative parts are attached to them, and these are shipped.

Activation

Filling of electrolyte

Capacity test

Electrolyte level

adjustment

Tightening adjustment

Packing